APPENDIX 3 Oxygen Deficiency Hazards (ODH)

(Taken largely from CEBAF Cryogenic Safety Manual)

Definitions

Oxygen Deficiency – the condition of the partial

pressure of atmospheric oxygen being less that 135 mmHg (about 18% by volume at

a barometric pressure of 740 mmHg at ANL).

[American Conference of Governmental Industrial Hygienists]

Procedures

1. A quantitative assessment of the increased risk of fatality from (potential) exposure to

reduced atmospheric oxygen shall be conducted for all operations which are

physically capable of exposing individuals to an oxygen deficiency. This assessment shall specify the Oxygen

Deficiency Hazard Class as well as any unusual precautionary requirements.

2. Precautionary measures shall be

implemented according to the ODH Class unless otherwise stated in the risk

assessment. ODH Class 0 is the

least hazardous and requires no special precautions. ODH Class 4 is the most hazardous and

requires the greatest precautions.

Effects

of Exposure to Reduced Atmospheric Oxygen

Air normally

contains about 21%1 oxygen with the remainder consisting mostly of

nitrogen. Individuals exposed to

reduced-oxygen atmospheres may suffer a variety of harmless effects. Table I contains a list of some of these

effects and the sea level oxygen concentrations at which they occur. At higher altitudes the same effects

generally occur at greater volume concentrations since the partial pressure of

oxygen is less. If exposure to

reduced oxygen is terminated early enough, effects are generally

reversible. If not, permanent

central nervous system damage or lethality result. Major effects hindering escape from the

vicinity of an oxygen deficiency are disorientation and unconsciousness.

In general,

the intensities of the effects increase rapidly with falling oxygen

concentration and longer exposure duration: reduced abilities, then unconsciousness,

then death. It can be concluded

that any exposure to an atmosphere containing less than 17% oxygen presents a

risk.

1Although this section is written in terms of %O2

at sea level, the preferred index of hazard is partial pressure of O2. Percent O2 is used here to

maintain consistency with the “readouts” on oxygen monitors.

TABLE I.

Effect Thresholds for

Exposure to Reduced Oxygen

(Healthy Individuals

at Sea Level)

|

|

Effect

|

|

|

|

|

17

|

Night vision reduced

|

|

Increased breathing volume

|

|

Accelerated heartbeat

|

|

|

|

16

|

Dizziness

|

|

Reaction time for novel tasks doubled

|

|

|

|

15

|

Impaired attention

|

|

Impaired judgment

|

|

Impaired coordination

|

|

Intermittent breathing

|

|

Rapid fatigue

|

|

Loss of muscle control

|

|

|

|

12

|

Very faulty judgment

|

|

Very poor muscular coordination

|

|

Loss of consciousness

|

|

Permanent brain damage

|

|

|

|

10

|

Inability to move

|

|

Nausea

|

|

Vomiting

|

|

|

|

6

|

Spasmatic breathing

|

|

Convulsive movements

|

|

Death in 5-8 minutes

|

ODH Risk

Assessment

The goal of ODH risk assessment is to estimate the rate at

which fatalities will occur as a result of exposure to reduced-oxygen

atmospheres.

Since the level of risk is tied to the nature of the operation,

the fatality rate shall be determined on an operation-by-operation basis. For the given operation several events

may cause an oxygen deficiency.

Each even has an expected rate of occurrence and each occurrence has an

expected probability of killing someone.

The oxygen deficiency hazard fatality is defined as:

(1) (1)

where f = the ODH fatality rate (per

hour)

Pi = the expected rate of the ith event

(per hour), and

Fi = the fatality factor for the ith event.

The summation shall be taken over all events which may cause

oxygen deficiency and result in fatality.

When possible, the value of Pi shall be determined by

operating experience at ANL; otherwise, data from similar systems elsewhere or

other relevant values shall be used.

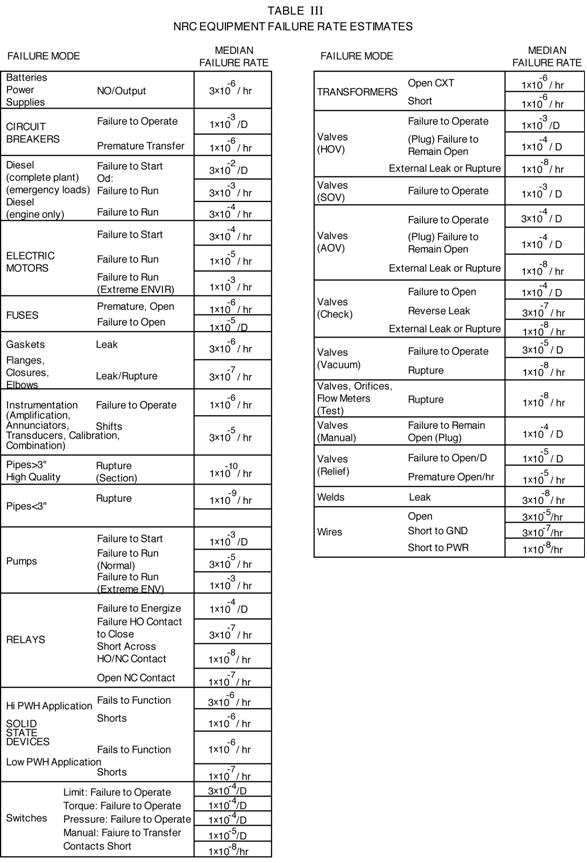

Estimates of “spontaneous” equipment failures

rates are given in Tables II and III.

The former contains median estimates collected from past ODH risk

assessments at Fermilab. The latter

contains values derived from the nuclear power industry.

General human error rate estimates are presented in Table

IV. Table V lists conservative

estimates of the rate of human error as a function of task type and time limit.

TABLE II

Fermilab Equipment

Failure Rate Estimates

|

Failure Mode

|

Estimated Media

Failure Rate

|

|

|

|

|

|

Compressor

(Cryogenic)

|

Leak or Rupture

|

3 x 10-5/hr

|

|

|

|

Dewar

|

Leak or Rupture

|

1 x 10-6/hr

|

|

|

|

Electrical Power Failure

(unplanned)

|

Time Rate

(Time Off)

|

|

|

|

|

|

|

Fluid Line (Cryogenic)

|

Leak or Rupture

|

3 x 10-6/hr

|

|

|

|

Magnet (Cryogenic)

|

Leak or Rupture

|

1 x 10-6/hr

|

|

|

|

U-Tube Change

Release

(Cryogenic)

|

Large Event

|

1 x 10-3/hr

4 x 10-5/hr

|

Human Error Rate

Estimates

10-3 Selection

of a switch (or pair of switches) dissimilar in shape or location to the

desired switch (or pair of switches), assuming no decision error. For example, operator actuates

large-handled switch rather than small switch.

3 x

10-3 General

human error of commission, e.g., misreading label and therefore selecting wrong

switch.

10-2 General

human error of omission where there is no display in the control room of the

status of the item omitted, e.g. failure to return manually-operated test valve

to proper configuration after maintenance.

3 x

10-3 Errors

of omission, where the items being omitted are embedded in a procedure rather

than at the end as above.

1/x Given

that an operator is reaching for an incorrect switch (or pair of switches), he

selects a particular similar-appearing switch (or pair of switches), where x =

the number of incorrect switches (or pair of switches) adjacent to the desired

switch (or pair of switches). The

1/x applies up to 5 or 6 items.

After that point the error rate would be lower because the operator

would take more time to search.

With up to 5 or 6 items he doesn’t expect to be wrong and,

therefore, is more likely to do less deliberate searching.

10-1 Monitor

or inspector fails to recognize initial error by operator. Note: With continuing feedback of the error on

the annunciator panel, this high error rate would not apply.

10-1 Personnel

on different work shifts fail to check condition of hardware unless required by

check or written directive.

5 x 10-1 Monitor

fails to detect undesired position of valves, etc. during general walk-around

inspections, assuming no checklist is used.

.2 - .3 General

error rate given very high stress levels where dangerous activities are

occurring rapidly.

2(n-1)x Given

severe time stress, as in trying to compensate for an error made in an

emergency situation, the initial error rate, x, for an activity doubles for

each attempt, n, after a previous incorrect attempt, until the limiting

condition of an error rate of 1.0 is reached or until time runs out. This limiting condition corresponds to

an individual’s becoming completely disorganized or ineffective.

TABLE V

Human Error

Rate as a Function of Response Time

Response

Time(s)

|

Maximum Estimated Error Rate (D-1)

|

Skill Based Task

|

Rule Based Task

|

Knowledge Based Task

|

|

|

|

|

|

|

10-4

|

37

|

600

|

18,000

|

|

10-3

|

26

|

300

|

10,000

|

|

10-2

|

16

|

130

|

4,900

|

|

10-1

|

8.7

|

42

|

1,800

|

|

5 x 10-1

|

4.0

|

10

|

550

|

Skill-Based

Task – An individual initiates a single-step learned response upon

receipt of an unambiguous sensor cue.

(Example: A lone worker

initiates escape upon hearing an oxygen deficiency alarm.)

Rule-Based

Task – An individual or small group of individuals diagnoses and

initiates corrective actions for a simple problem given limited or ambiguous

input. (Example: Several workers decide whether or not to

escape given that one of them passes out but no oxygen deficiency alarms

sound.)

Knowledge-Based

Task – A group of individuals diagnoses and initiates corrective

actions for a novel and/or complex problem.

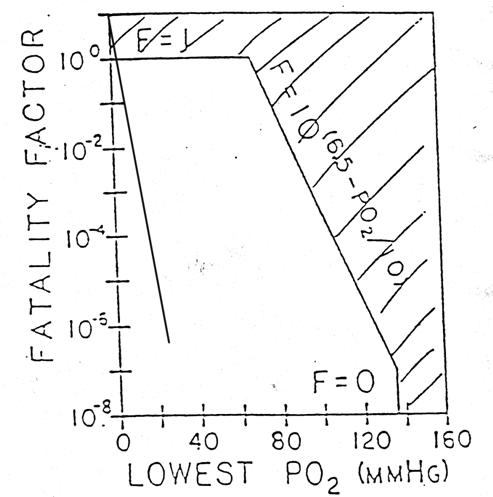

The value

of Fi is the probability that a person will die if the ith event

occurs. This value depends on the

oxygen concentration, the duration of exposure and the difficulty of

escape. For convenience of

calculation, a relationship between the value of Fi and the lowest

attainable oxygen concentration is defined (Figure 1). The lowest concentration is used rather

than an average since the minimum value is conservative and not enough is

understood to allow the definition of an averaging period. If the lowest oxygen concentration is

greater than 18%, then the value of Fi is zero. That is, all exposures above 18% are

defined to be “safe” and to not contribute to fatality. It is assumed that all exposures to 18%

oxygen or lower do contribute to fatality and the value of Fi is

designed to reflect this dependence.

If the lowest attainable oxygen concentration is 18%, then the value of

Fi is 10-7.

This value would cause 0 to be 10-7 per hour if the expected

rate of occurrence of the event were one per hour. At decreasing concentrations the value

of Fi should increase until, at some point, the probability of dying

becomes unity. That point was

selected to be 8.8% oxygen, the concentration at which one minute of

consciousness is expected.

Fig. 1. Graph of the logarithm of the fatality factor

(Fi) versus the lowest attainable oxygen concentration which can

result from a given event. This

relationship should be used when no better estimate of the probability of

fatality from a given event is available.

The oxygen concentration is a confined volume during and

after a release of inert gas may be approximated from the following

differential equation

(2) (2)

V

= the confined volume (ft3 or m3)

C

= the concentration of oxygen

R

= the spill rate into the confined volume (cfm or m3/s)

Q

= the rate of ventilation through the confined volume (cfm or m3/s).

In order to solve this differential, the following

assumptions are made:

·

Complete, instantaneous mixing takes place in

the confined volume

·

V, R, Q, and the total pressure remain constant

·

The initial oxygen concentration is 21%.

Therefore, the oxygen

concentration during the release is

(3) (3)

where t is the time from the start of the release. After the release has ended, the oxygen

concentration is

(4) (4)

where t is the time after the end of the release (when R

becomes zero) and te is the duration of the release.

Once the ODH fatality rate (f) has been determined, the

operation shall be assigned an ODH class according to Table VI.

TABLE VI

Oxygen Deficiency

Hazard Class

4.

Gas dynamics

a.

Ventilation

i.

Natural

ii.

Forced

b. Stratification/mixing

c.

Diffusion

|